-

Email : mike.zhang@baot.biz

Email : mike.zhang@baot.biz

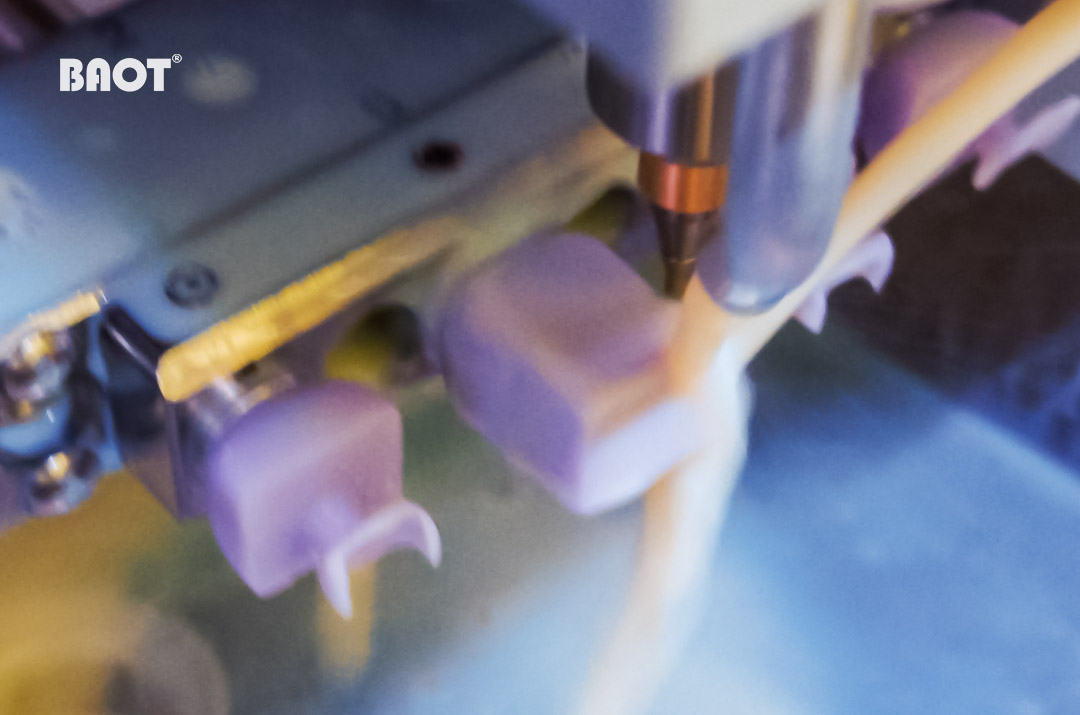

In the world of modern dentistry, precision and efficiency are paramount. This is where dental milling machines come into play. These small yet powerful cutting machines are equipped with CAD/CAM systems, which stand for Computer-Aided Design and Computer-Aided Manufacturing. Their primary purpose? Crafting prosthetics like fillings and crowns, restoring the smiles of those missing teeth.

The process is fascinating – a disc-shaped dental material, often referred to as a "disc," is meticulously shaped into the form of a tooth by the milling machine. This intricate task is executed with the help of a specialized tool known as a milling bar. These machines work with a variety of materials, each chosen for its unique properties and suitability for different dental applications. Common materials include non-metallic options like zirconia, ceramics, wax, and PMMA (acrylic resin), as well as metals such as titanium and cobalt. The choice of material depends on factors like durability, resistance to discoloration, and the desired finish.

Are Dental Milling Machines Increasingly Being Utilized?

The short answer is yes, and there's a compelling reason for this trend. Currently, there's a shortage of dental technicians and their work style is facing challenges. In China, for instance, one in six people (more than 2.1 billion individuals) rely on dentures. To meet this demand, there are around 30,000 dental laboratories in the country.

The future paints a picture of even greater reliance on prosthetics, thanks to China's aging population. However, the shortage of dental technicians can be attributed to factors like income and working conditions. This situation is where dental milling machines step in.

As the demand for dental care rises in an aging society, the workload of dental technicians is expected to surge. Milling machines offer a solution by automating the prosthetic crafting process, effectively reducing the burden on technicians. They are poised to become indispensable equipment in the field of dentistry.

Types of Dental Milling Machines

Dental milling machines come in three main types: dry, wet, and combination dry/wet models. Let's explore each one:

1. Dry Method: This method operates without the use of water or coolant during processing. It's ideal for cutting soft materials like zirconia, resin, and PMMA using small-diameter tools in the 0.5mm range. This precision makes it perfect for fine modeling. However, it's not as suitable for cutting hard materials due to potential tool breakage and longer machining times.

2. Wet Method: In this method, water or coolant is applied during processing to reduce frictional heat while polishing. It is primarily used for processing hard materials like glass ceramic and titanium, which are popular among patients for their durability and aesthetic appeal.

3. Combination Dry/Wet Method: This is a versatile model that accommodates both dry and wet processing. While it can process a variety of materials with a single machine, it has some drawbacks, such as non-productive time when switching between wet and dry processing. Cleaning and drying the machine can be time-consuming. Also, these dual-use models might not be as efficient as dedicated machines for specific tasks.

Choosing the right milling machine depends on factors like material characteristics and frequency of use. Dental professionals need to select the method that best aligns with their specific requirements.

TP5 Milling Machine: The Advanced Choice for Dental Precision

The TP5 Milling Machine offers a comprehensive range of features, combining 5-axis linkage capabilities for precise and intricate milling tasks. Its user-friendly interface integrates a computer and touchscreen, making operation simple and straightforward. The machine employs a high-precision lead screw guide rail system to ensure accuracy in milling, and its robust one-piece aluminum structure maintains mechanical precision over extended periods. Enhanced by an efficient cooling system, a high-performance spindle with tool change capabilities, and the ability to resume milling after a power failure, it excels in functionality. Furthermore, the TP5 provides responsive after-sales support and offers online remote maintenance assistance.

The TP5 Milling Machine can process various materials, including metals such as titanium blocks and titanium columns, as well as projects involving glass ceramic full crowns, inner crowns, veneers, inlays/onlays, and bridges. The average milling times for different projects range from 2 minutes to 1 hour, ensuring efficient completion of a wide range of dental procedures. This comprehensive suite of features makes the TP5 Milling Machine the top choice in the field of dentistry.

TZ5 Dental Milling Machine: Precision, Versatility, and Efficiency

The TZ5 milling machine is an innovative and versatile device with high-precision five-axis linkage, excelling in various milling tasks to ensure clear shoulders and minimize post-grinding work. It employs a full servo drive system with high-precision lead screw guide rails for stability and reliability. Additionally, it features an integrated cooling system and a liquid circulation pump. With a high-precision, high-frequency, and high-speed spindle, it proves to be an efficient milling machine. Timely after-sales support and online remote maintenance services are available.

Moreover, it has a power failure recovery feature with an intelligent memory processing program. This machine is suitable for processing materials such as titanium columns, glass-ceramic blocks, HPP, and PMMA blocks, with impressive average milling times, for example, 15-18 minutes for PMMA provisional teeth, 15-20 minutes for metal abutments, 25-30 minutes for glass ceramic full crowns, 20-25 minutes for inner crowns, 20-30 minutes for veneers, 25-40 minutes for inlays/onlays, and 40-60 minutes for bridges. Whether it's speed or efficiency, the TZ5 excels as a dental milling machine.

In conclusion, dental milling machines are a crucial innovation in the field of dentistry, offering precision and efficiency in prosthetic creation. As the demand for dental care continues to grow, these machines will play an increasingly essential role in ensuring that patients receive top-notch dental solutions.